Safety and know-how

Chemical logistics

HOYER develops and implements solutions relating to the handling and the national and worldwide transport of liquid chemical products, irrespective of whether they are dangerous goods or harmless substances. The raw materials that we transport include isocyanates, polyols, ethanol, oils and dispersions. In addition to the automobile, pharmaceuticals and cosmetics industries, applications of chemical raw materials can also be found in almost all everyday articles. We also give top priority to flexibility, safety and sustainability when handling chemical products.

Integrated logistics solutions: Efficient and sustainable

HOYER not only carries out road transport and intermodal transport operations, but can also undertake complete control of the entire flow of goods and information from start to destination – both for high-value special products and for standardised bulk goods.

We developed the Smart Tank and the associated Smart Portal for efficient, digitally-assisted fleet management. Intelligently networked technologies offer unbeatable added value with regard to safety, quality, transparency, economic efficiency and sustainability – at all stages in the logistics chain. And apropos value added: With a large proportion of intermodal transport movements and the shift away from road and towards rail, HOYER actively helps to reduce CO2 emissions in logistics.

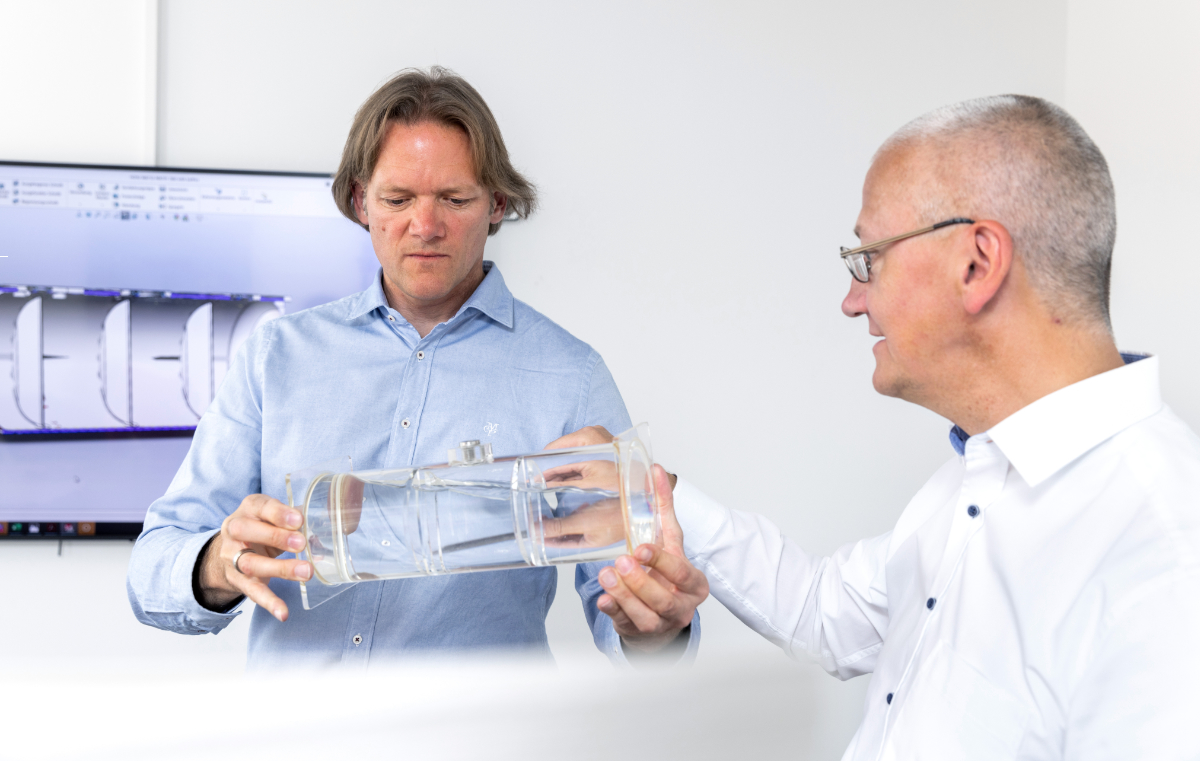

Our special equipment in use for you

For chemical shipments, we use a variety of modern tank containers in different sizes as well as special equipment and road tankers. With our Flexitanks, manufactured to European quality standards, we offer a tailor-made logistics solution with global availability that is ideal for small and medium quantities of non-dangerous chemical products.

Intermodal and overseas transports of liquid chemical products are carried out in tank containers; we also use road tankers for road transports in European traffic. In Europe, Asia and North America, Intermediate Bulk Containers (IBCs) are also used for small volumes. In addition to standard tank containers, we also offer customised products tailored to your customers' individual needs and requirements, and provide special equipment.

- Standard 20-foot tank containers with various transport volumes (with and without baffle walls)

Swap-body tank containers (7.15 m and 7.82 m standard size, various transport volumes with and without baffle walls)

Innovative insulation techniques for hot and cold insulation

Intelligent, environmentally friendly heating systems

Pump equipment and lined tank containers

Refrigerated tank containers with integrated cooling and heating technology

Tank containers with newly-developed heating systems

Titanium and alloy tank containers

Our tank containers can be equipped with various sensors that record pressure, temperature and other data.

Incidentally: All the IBCs and tank containers can also be leased from us. On request, we fabricate special designs with our partners.

more about our equipment

more about our IBC logistics

OUR SERVICES

Careful procedure is crucial when transporting and handling sensitive chemical products in tank containers. HOYER maintains high standards and draws on decades of experience in dealing with a wide variety of liquid goods. As a customer, you can devote yourself to your core business while we take care of their smooth transport. Our aim: To manage container flows for you optimally and in line with your needs – all in the spirit of efficient logistics. Our services include:

Worldwide implementation

Attractive freight rates

Reverse logistics

Reliable execution

With our fleet size and our global network, customers all over the world profit from our renowned quality. We do a lot for this quality: We want not only to meet our customers' diverse and increasing requirements for the transport and storage of their goods, but to exceed them. Therefore we constantly invest in the technical development of our tank container fleet.

We help you to optimise your on-site logistics and to make the entire supply chain more efficient. HOYER takes care of all services along the supply chain, from project development to implementation: The precise blending of the raw materials of almost any liquid chemical product is just as much a part of this as the storage and handling of dangerous materials. With our highly qualified employees, specialised know-how and a high degree of safety and quality awareness, we are a strong added value in the value creation chain of chemical logistics.

Our services include:

On-site logistics

Filling and accurately-formulated blending

Contract warehousing

Operating intermodal terminals

Dangerous goods storage in tank containers

Handling and storage of plastics

Project development

- Integrated logistics solutions

We undertake both the operational and the strategic management of containers for you. We determine the requirements and take over the control and monitoring of the containers as well as their technical management. With IT systems specially designed for the purpose, we map container stocks and goods flows within the supply chain transparently, even across companies. Thus we not only create transparency but also support you in breaking new ground and integrating optimised logistics solutions into your business. Our services include:

Optimising downtimes

Overview of the tank container locations

Fleet size optimisation

Increasing flexibility

Our container services include servicing and repairing tank containers and road tankers. We also provide both safety inspections and periodic inspections from a single source. We even modify special equipment in our own workshops.

Specialists in our certified cleaning plants take care of the external and internal cleaning of tank containers. The handover is rounded off with a cleaning certificate from SQAS-certified cleaning stations.

In the affiliated depots, we undertake the storage of empty and full containers. Storage of dangerous goods and heating or cooling are also possible at some sites. Our services include:

Heating or cooling of containers

Repairs and modifications

Depot storage of full and empty containers

Product-specific cleaning, including certificates

Uniform cleaning process standards

Environmentally correct disposal of product residues

YOUR CONTACT PARTNER

![[Translate to English:] Jennifer Hein HOYER Group Supply Chain Services](/fileadmin/user_upload/Jennifer_Hein.jpg)